JAMG HE ASA Black Filament 1.75mm 1kg

317.27 DH (HT)

En stock (peut être commandé)

Description

✅ What is ASA filament (and why you’d pick it)

-

ASA stands for “Acrylonitrile Styrene Acrylate” — a thermoplastic polymer formulated for 3D printing (FFF / FDM).

-

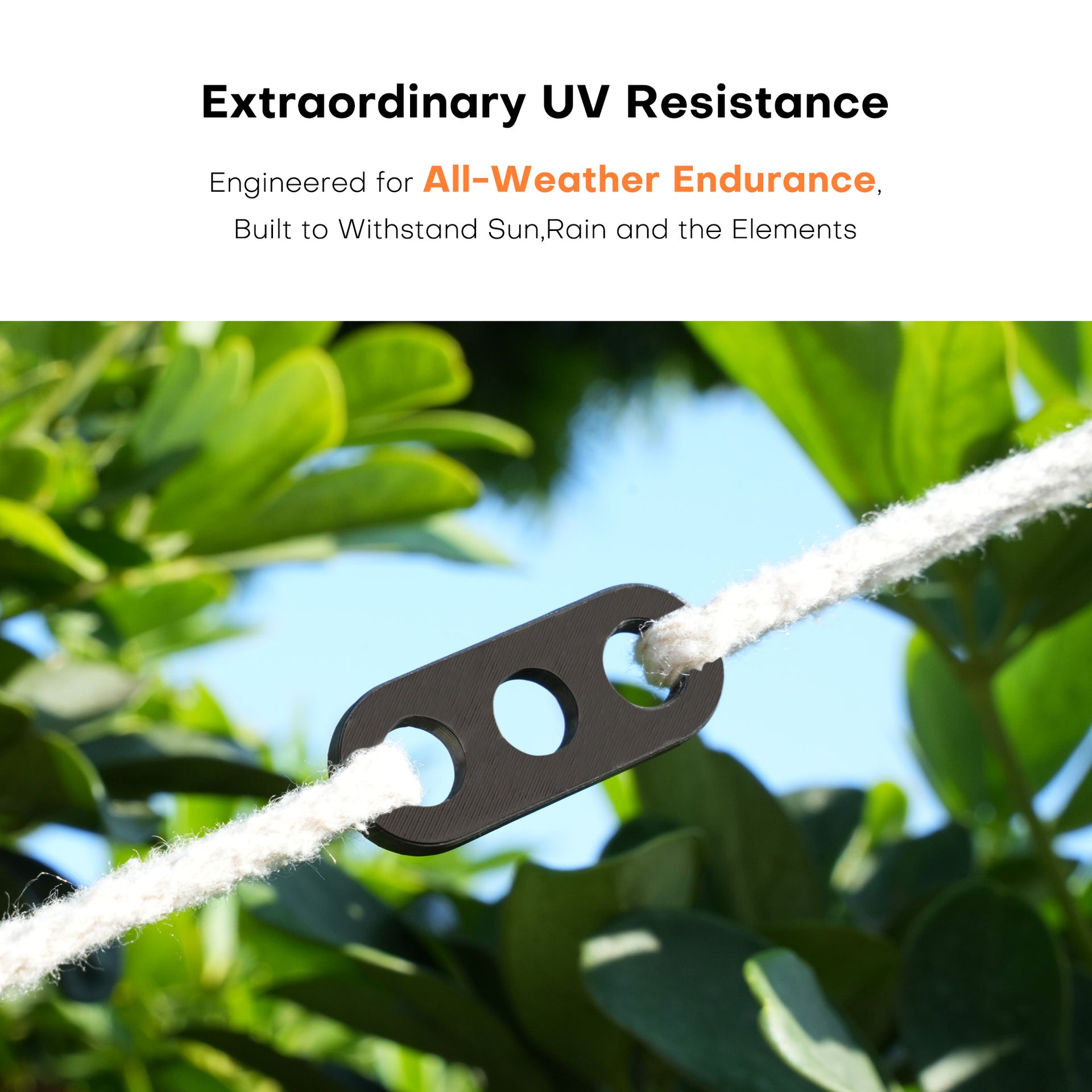

ASA is favored when you need parts that can withstand outdoor exposure or demanding conditions. Compared to simpler materials (like PLA), ASA offers much better resistance to UV light, weather, moisture, temperature changes, and many chemicals/solvents.

-

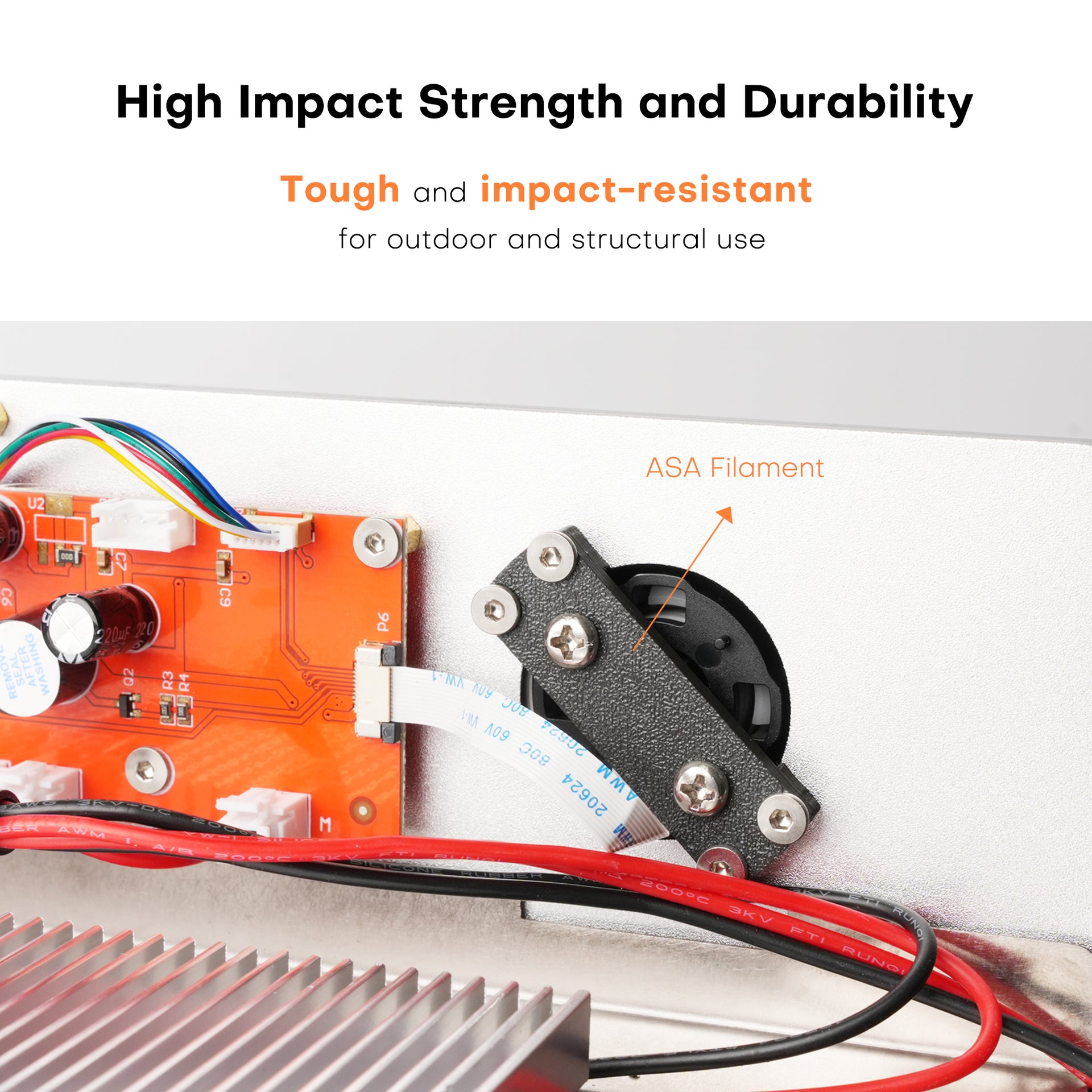

Mechanically, ASA tends to combine good impact resistance, toughness, rigidity, and relatively high strength, often described as similar to (or better than) older ABS filament, but with improved environmental/weather resistance.

-

Because of that, ASA is well suited for functional parts, mechanical components, enclosures, outdoor fixtures, automotive parts, housings, and other prints exposed to sun, rain or heat.

So if you use the JAMG HE ASA spool, you’re using a filament designed for long-lasting, robust prints — not just decorative objects.

📦 Physical / Technical Specifications (typical for ASA, likely for JAMG HE spool)

While I couldn’t find a public technical sheet specifically for “JAMG HE ASA”, ASA data sheets from various manufacturers suggest the following typical parameters:

| Parameter / Attribute | Typical Value / Detail |

|---|---|

| Diameter | 1.75 mm (standard for many FDM printers) |

| Spool Net Weight | 1 kg (as indicated by product title) — meaning about 1 kg of filament material on the spool. |

| Dimensional Tolerance | Often around ± 0.02 mm to ± 0.05 mm depending on brand. |

| Density | Typical ASA density ~ 1.07–1.08 g/cm³ (depending on formulation). |

| General Material Form | Filament — wound onto a spool, vacuum-packed with desiccant to reduce moisture absorption. |

🔧 Typical 3D-Printing / Handling Guidelines for ASA

Based on widely used guidelines for ASA filaments. Actual optimal settings may vary depending on your printer, environment (ambient temperature, enclosure, etc.), and part geometry.

-

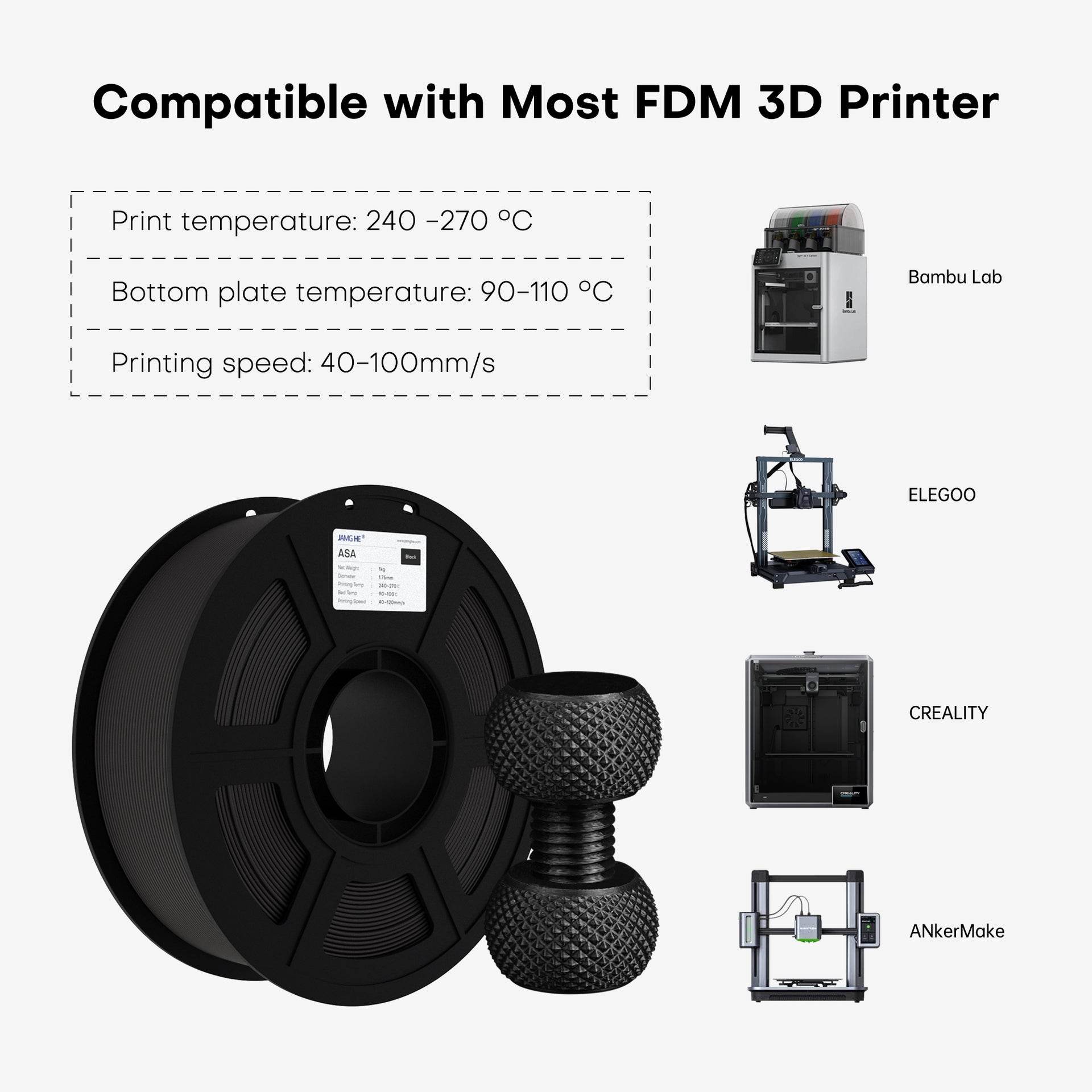

Nozzle / Extruder Temperature: ~ 230–260 °C.

-

Heated Bed Temperature: ~ 70–110 °C (many manufacturers recommend 90–100 °C, but 70 °C may suffice depending on part and printer).

-

Cooling / Fan Use: Minimal or no part-cooling fan recommended (0–50%) to improve layer adhesion and avoid warping.

-

Chamber / Enclosure: Printing with a closed or semi-enclosed chamber (or at least reduced drafts) helps — ASA tends to benefit from stable ambient temperature to prevent warping or cracking when cooling.

-

Drying / Storage: ASA is hygroscopic (absorbs moisture). Filament should be stored in a dry place, ideally in a sealed container with desiccant. Some ASA manufacturers recommend drying filament before printing (e.g., 3–6 hours at ~ 60–80 °C) if it’s been exposed to humidity.

Because the spool is likely vacuum-packed with desiccant, that helps preserve filament quality — but if your environment is humid (common in many places), it’s often a good idea to dry before use.

✅ Advantages & Use-Cases for JAMG HE ASA Filament

Using ASA (with a spool like JAMG HE 1.75 mm 1 kg) gives you advantages especially when you want:

-

Outdoor-ready parts — prints that won’t quickly degrade under sunlight, rain, heat or UV exposure (e.g., garden tools, housings for outdoor electronics, mounts, outdoor signage).

-

Functional / mechanical parts where strength, impact resistance, stiffness, and durability matter (e.g., in tools, enclosures, mechanical components, car parts, prototypes subject to wear).

-

Thermal stability — better heat resistance than PLA, meaning your parts maintain integrity at higher temperatures.

-

Long term reliability — because of weather/UV/chemical resistance, ASA is preferred for parts that should last.

For a 3D-printing hobbyist or maker working in Casablanca (or anywhere with sun / heat), ASA offers a practical upgrade over PLA or basic filaments — especially if prints will be used outdoors or under stress.

⚠️ Considerations / Challenges when Printing with ASA

That said, ASA is not as “easy” as PLA (or even some PETG) in all respects. Common challenges or trade-offs:

-

Requires a printer capable of high nozzle temperature (often 230–260 °C) and a heated bed with sufficiently high bed temperature. Not all entry-level printers may handle this reliably.

-

Warpage / layer adhesion / bed adhesion — because of thermal contraction, ASA can warp or lift if bed adhesion / bed temperature / print-chamber conditions aren’t optimal.

-

Moisture sensitivity — if filament absorbs moisture, prints may suffer (bubbling, poor layer bonding, stringing). So storage and possible pre-drying matters.

-

Potential fumes — some ASA prints may release stronger smells than PLA during printing; good ventilation is recommended.

So printing ASA successfully often requires more careful temperature & environment management than simpler filaments.

Vous aimerez peut-être aussi…

-

SUNLU 3D Filament Dryer

453.64 DH (HT) Ajouter au panierDisponible sur commande